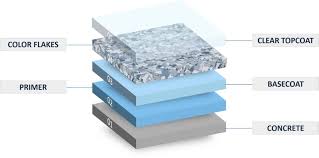

Polymers are materials composed of long, repeated chain of molecules. They are materials are unique in their properties that vary based on the kind of molecules that are bonded and the method by which they are joined. Certain polymers stretch and bend like polyester and rubber. Other polymers are strong and durable such as glass and polyurea.

Polymers are everywhere in the course of modern-day life. Most likely, you’ve interacted with an item containing polymers including water bottles to devices within the last five minutes.

“Polymer” is a term often used to describe plastics, polymers made from synthetic materials. However, there are also natural polymers like wood and rubber, for instance, natural polymers composed of a basic hydrocarbon called isoprene, as per Encyclopedia Britannica. Proteins are polymers that are composed of amino acids. Nucleic Acids (DNA and DNA and) are nucleotide-based polymers complex molecules comprised of nitrogen-containing sugars, bases, and phosphoric acid, an example.

Chemical reactions

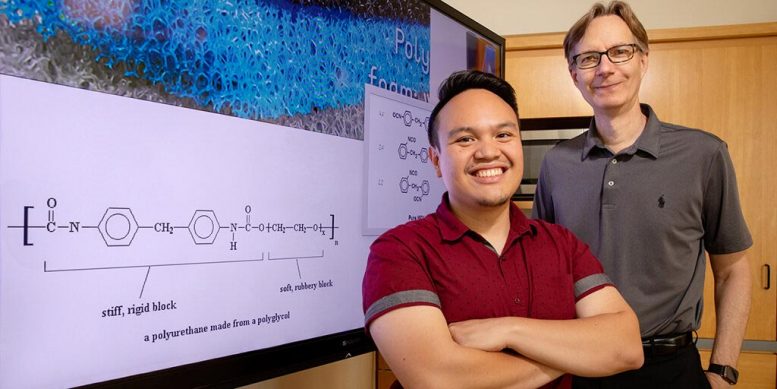

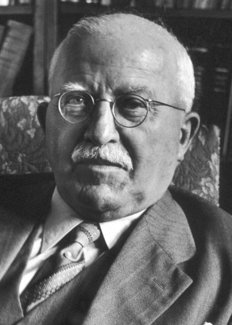

Hermann Staudinger, a professor of organic chemical chemistry in the Eidgenossische Technische Hochschule (University of Science and Technology) in Zurich is the father for modern polymer development. His research during the 1920s paved the way to modern techniques for manipulating both organic and synthetic polymers. He invented two words that have become crucial to understand macromolecules and polymerization in the words of the American Chemical Society (ACS). He was awarded the Nobel Prize in Chemistry in 1953 “for his contributions to the study of macromolecular chemical research.”

Polymerization is the process of making synthetic polymers by mixing smaller molecules known as monomers into a chain, held through covalent bonds, as per ThoughtCo. It is an online resource for education. There are a variety of chemical processes — such as those that are caused by heat or pressure for instance -are able to change those chemical bonds which hold monomers together as per Scientific American. The reaction causes the molecules to bond together in an elongated, branched or network and create polymers.

Monomer chains are also known as macromolecules. The majority of polymer chains contain carbon atoms as their backbone. A single macromolecule may comprise several hundred thousand monomers as per the Polymer Science Learning Center.

Polymers are used for a variety of purposes.

Polymers are utilized in nearly every aspect of modern life. Food bags, soda and bottle of water, fiber-based textiles computers, phones automotive parts, food containers and toys all have polymers.

More sophisticated technologies also use polymers. For instance, “the membranes for water desalination, the carriers in controlled release of drugs and biopolymers that are used in tissue engineering all utilize the polymer,” as per the ACS.

The most popular polymers used in manufacturing are polypropylene and polyethylene. The molecules of these polymers can range from between 10,000 and 200 monomers.

In a polymerization process, numerous monomers join together through covalent bonds, forming an incredibly long molecule. This is called a polymer.

The future of polymers

Researchers are testing different polymers, in the hope of advancing medical research and improve the existing products.

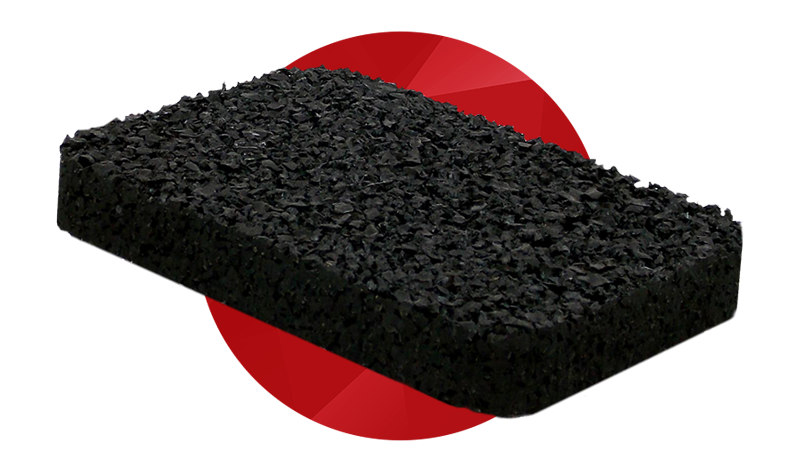

For instance carbon polymers are being developed and refined to be used in the automotive industry.

“Carbon-fiber-reinforced polymer (CFRP) composites — also called carbon-fiber laminates — are the next-generation materials for making cars lighter, more fuel efficient and safer,” according to a 2016 Live Science column by Nikhil Gupta, an associate professor, and Steven Zeltmann, a student researcher, both in the Composite Materials and Mechanics Laboratory of the Mechanical and Aerospace Engineering Department at New York University Tandon School of Engineering. “Carbon laminates are extremely durable and rigid due to its interwoven layers of almost pure carbon fibers, which are joined with a hardened polymer, like epoxy resin.” ” “The future of carbon fibers: it’s about more than speed.

Polymers are also being utilized to enhance the quality of holograms. Researchers at the University of Pennsylvania created a Hologram made of a flexible polymer material known as PDMA which was embedded with gold nanorods according to a research study published in the beginning of 2017 online by the journal Nano Letters. The new hologram technology can store multiple images rather than just one.

“The problem we faced was”Can we encode multiple pieces of information into the hologram?'” Ritesh Agarwal, research leader and professor of materials engineering and science in the University of Pennsylvania, said to Live Science. “It’s an important aspect of work because it’s also the first time that someone has demonstrated that the ability to record multiple holographic images and by simply stretching the polymer it is possible to alter the appearance of the appearance of the image.”

Artificial skin composed of an elastomeric polymer could be the next step in anti-aging treatments. As two creams that contain the polymer could firm the skin of a person as well as reduce wrinkles and lessen the appearance of under-eye bags according to a research study published in May 16, 2016 within the scientific journal Nature Materials. Artificial skin can also help sufferers of skin issues like eczema or as a sunblock.

“We are thrilled about it because it’s a new material,” study co-author Robert Langer, a professor at the Massachusetts Institute of Technology, said on Live Science.